EPS is a closed cell, lightweight, foamed plastic which has a compression strength between 10 to 33 PSI for most construction applications. Applied in roofing, foundations, and walls. EPS has a successful history of efficient use in industrial, commercial, residential and cold storage buildings.

EPS is a closed cell, lightweight, foamed plastic which has a compression strength between 10 to 33 PSI for most construction applications. Applied in roofing, foundations, and walls. EPS has a successful history of efficient use in industrial, commercial, residential and cold storage buildings.

EPS insulation (1 lb. per cubic foot) provides a typical R-value of 3.9 per inch at mean temperature of 75° F. The R-value of EPS insulation is permanent because the cellular structure of EPS contains only stabilized air. It's R value will not decrease as it ages.

Exterior Sheathing

- Meets or exceeds current energy conservation design standards without increasing stud width.

- Reduces air infiltration and heat loss through framing; slows convective looping.

- Corner bracing required for non-structural sheathing.

- Foil-faced EPS with air space can provide additional R-value; retards radiant heat flow.

- Peforated foil promotes breathability.

- Elimiates need for extra-deep framing.

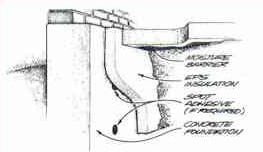

Perimeter Insulation

Perimeter Insulation

- Select strength and thickness to meet loading and thermal requirements.

- Long-term resistance to slab edge heat loss

Eave Vents

- Allow air to enter at the eave and move out hot, energy-robbing attic air in summer and damaging attic air in the winter.

- Proper roof ventilation eliminates the potential damaging ice build-up at eaves and valleys.